Deacom 15.02 Release Notes

Please reference the DEACOM suggested update path prior to installing DEACOM updates.

Accounting

- WIP Materials Account Moved – The "Accounts" tab on the Item Master record now contains a "WIP Materials" field. This field acts as the override to the value in System > Options. Added to support situations where customers prefer to have a specific product or group of products hit in a specific inventory category WIP account. When updating to version 15.2, a dxpop entry will add the WIP Material account from system options to the WIP Material item master account. In addition, when creating a new item master, the WIP Material account default will be provided by the WIP Material account in system options.

- 1099 Form Types - 1099 Form Types have been added to allow customers to differentiate various 1099 types and which 1099 forms to use (1099-MISC, 1099-DIV) during purchase order entry. Once the form types have been created via Purchasing > Purchasing Maintenance > 1099 Form Types, they may be added to Vendor master records in order to act as the default when new purchase orders for this vendor are created. If the Vendor does not have a default 1099 Form Type, users may select one manually during purchase order entry. When viewing the purchase order, the 1099 Form Type is displayed on the "Misc 2" tab.

- Journal Entry Record History - The "Record History" button via the More dropdown menu now displays information regarding who entered the journal entry when running the Journal Entries report via Accounting > Accounting Reporting.

- Post Depreciation for Multiple Work Centers - The Post Depreciation G/L button has been added to the Work Centers form via Production > Production Maintenance > Work Centers. If this button is clicked, allows users to Post Depreciation for all the visible Work Centers in a single click.

- Report Grid Totals now Available when Exporting to Excel - When exporting accounting reports to Excel, the totals at the top of the grid will be pulled into the Excel spreadsheet when the "Sum" flag (b2_sum) is checked on the Edit Grid Column form for any column in the report grid.

Calendars

- "Entered By" Field Added on Sales Calendar - The "Entered By" field has been added to the calendar pre-filter form in web versions only. The field is only enabled when selected a calendar type of "Sales" or "Sales Inventory". The field shows the user name of the person who entered the order.

- Calendar Colors Added to Job Work Flow Sequences - The "Calendar Color" field on the Edit Work Flow Sequence form can now be used to determine how Jobs will be displayed on the Job Calendar, not the Job Inventory Calendar, based on the color associated with the Job Work Flow Sequence.

CRM

- Sending Emails - When sending an email within CRM, the system will now automatically preview the body of the email in the "Notes" section of the Contact record.

EDI

- Allow Duplicate PO Numbers - New fields have been added to the General tab on the Bill-to and Ship-to master records to more easily allow for the import of duplicate PO numbers. Additional information is available via the Configuring Inbound EDI Transactions page.

Inventory

- Production Cost Expression Field - A new field, "Cost Expression", has been added to the "Production" tab via System > Options. If this field contains a valid expression, the system will use the result of the expression to populate the production cost (i.e. the lot cost for the material being placed into inventory) for material finished/produced on jobs in DEACOM. This field was added to support scenarios where the cost of finished material could not be done by volume or weight alone and required the ability for the user to configure an expression to support the cost calculation.

- Item Pick Order Option - A new field, "Pick Order", has been added to the "General 2" tab of the Item Master record. The field determines how lots of this part will be suggested, displayed and chosen when lots are automatically displayed by "Date Created" (fi_date) or "Expiration Date"(fi_expires) on the "Select Lots" form and the "Final Staging" forms throughout the main application and in the WMS application. Options are "FIFO" or "LIFO". If the "FIFO" option is selected, the system will suggest the oldest or closing to expiring lot. If "LIFO" is suggested, the system will suggest the newest lot, essentially the reverse of "FIFO" suggestions. "FIFO" is the default option for this field. Additional information is available via the "Pick Order" field description on the "General 2" tab help section via Inventory > Item Master Management.

- Pre-Stage Source Locations and Location Types - The "Source Location" and "Source Location Type" fields are now enabled on the pre-filter form via Inventory > Inventory Pre-Staging. The option was allow companies to filter lots that will be pre-staged based on the Source Location and Source Location Type where they are currently located.

- Default Move Quantity To Lot Balance Option - A new field, "Default Move Quantity to Lot Balance", has been added to the "Inventory 2" within System > Options. If checked, the "Move Quantity" on the "Move Inventory" form is defaulted to the lot balance whenever the On Hand/Balance Quantity is updated or refreshed on the form. This system option applies to the main DEACOM application and the Warehouse Management System. This feature was added to provide users with another default value option other than "0" when a new lot is selected on the "Move Inventory" form.

- Adjustment Reason Specific Accounts - The "Inventory Adjustment" field has been added to the "Edit Inventory Adjustment Reason" form via Inventory > Inventory Maintenance > Adjustment Reasons. This field, which is optional, allows users to define an adjustment account for a specific Adjustment Reason. If an account is entered in this field and the corresponding Adjustment Reason is specified when adjusting inventory via the "Inventory Adjustment" form, the system will use this adjustment account instead of the selected item's adjustment account.

- Multiple Sales Substitutions - DEACOM now supports multiple part substitutions during the sales reserving process. Complete information is available via the Utilizing Substitutes in Sales page.

- Item Master User Fields Added to Multiple Reports - Item Master User Fields have been added to the grid layout for the Lots, Lot Summary - User Lot, History, History Summary, Transaction, and Aged Inventory Management reports.

- De_issue All Security - A new security setting "Inventory - De-Issue All," has been added. If set to yes, users will not be able to use the "De-Issue" checkbox via Inventory > De-issue / Un-reserve.

- Item Master Fields Added to Bill of Materials Record - All Item Master Management (dmprod) fields are now available to the grid layout on the Edit Bill of Material form via Inventory > Formula Management.

- Master Lot Location Type and Location during Final Staging - When a Master Lot is selected in the "To Master Lot" field during final staging of inventory, the New Location Type and New Location fields will now be populated with the Location information of the chosen Master Lot. These fields, along with the Retain Current Location checkbox, are then disabled. This is done since a Master Lot, by definition, occupies one inventory location. During the final stage process the user may be staging multiple items. In this case, the requirement to re-select the Location Type and Location for each item is redundant.

- Restrict Locations to same Items - A new flag, "Restrict Locations To Same Item" has been added to the Item Master Properties tab. If checked, indicates the item is restricted to locations containing the same item. Applies to receiving, moving, issuing, finishing, and reserving, both in the main application and the Warehouse Management System. Users with security setting "Inventory -- override location restrictions" may override the restriction. Useful in situations where items may appear similar from the outside, such as packaging containers, but are in fact two different items.

- Master Lot search field added to Inventory Management pre-filter - selecting a master lot offers users a convenient option to filter reports that return excessive results; this simplifies the process of finding the correct Lot to move.

Business Case - A liquor distilling customer required the ability to cost their material by the "Proof Gallon" which is a calculation of two fields, proof and volume. The proof of the liquid and the amount of liquid varies from lot to lot due to the nature of the distilling process. In this case, the customer could not simply just cost by volume or proof, or even by weight. The cost of lots produced in this case was the result of the following expression: "volume = weight/density".

The DEACOM fields that may be used in the expression are listed in the "Cost Expression" field description via System > Options.

Business Case - The enhancement was added to support liquor distilling scenarios. For example, if a customer wishes to buy 6-month bourbon, it would makes more sense to sell a lot that is 7 months old rather than one that is 22 months old, and thus will be considered 2-year bourbon soon.

MRP/Forecasting

- BOM Revision selection for Jobs created in MRP - When using the "Create Job" or "Auto Job" buttons in MRP, the system will now allow users to select and modify the job(s) to change the Bill of Material revision and quantity. Users will not be able to change the "Planned Start" or "Planned Finish" dates. This feature was added for customers who have multiple revisions for same item and need to the ability to specifically choose what revision will be used on jobs created within MRP. Additional information is available via Entering Production Jobs Using the "Create Job" and "Auto Job" Functions. Note that this feature is only available in web based versions of DEACOM.

- Forecasts for Phantom Parts - DEACOM will now redirect Forecasts for Phantom parts to the Phantom part's Bill of Materials instead. Specifically, when gathering Forecasts in MRP, if a part on a forecasts is a Phantom part, the system will add that part's BOM for the quantity forecast to the forecast line/column in the MRP report instead. For more information on Phantom Parts, refer to Using Kitted Parts.

- Forecast Revenues Form Deal Pricing - Forecast revenues from deal pricing are now calculated assuming a quantity of the pricing unit rather than the sales unit.

- Maximum Bucket Number Changes - Time-phased MRP allows the following number of buckets: Days up to 180, Weeks up 120, and Months up to 60.

Part Forms

- Item Label Customer Part Information - When printing item labels from the customer part cross reference record (custpart2 form) the users now have the ability to add customer part cross reference user fields to the Item Label for the specific customer cross reference selected.

Printed Reports

- "Client Rendering" Defaults To True - The "Client Rendering" check box on the ""Edit Part Form" form for Part Forms will be set to "True" by default when updating to Version 15.02. This check box helps in situations where clients are experiencing delays in printing documents. If checked, this flag allows rendering on the device/client side as opposed to the server side. In this case, DEACOM will check the device/client side when verifying Active X Controls and appropriate drivers. The ability to uncheck the box is used primarily for diagnosing issues.

- Facility Information Available to Job Reports - Any field from the "Facilities" table (dmware) can now be added to the header section on "Job" type Report Layouts in DEACOM. Report Layouts are maintained via Print Outs > Print Outs Maintenance > Report Layouts. When printing report layouts from jobs in DEACOM, the system will print the facility information based on the facility specified on the job header. This ability was added to support situations in which customers wish to print the name of the facility on the batch ticket for the job.

- Master Lot Information for Staging Picklists - All fields in the Master Lot table (dtmasterlot) are now available to the staging and final staging picklists, both when printing from the issuing screen as well as the pre-staging screen.

Production

- Master Lots and Pick List suggestions - A new flag, "Include Master Lots In Picklists" has been added to the "Production" tab via System > Options. If checked, the system will allow inventory issued to Master Lots to be included and available for selection when printing the pick list. An example, below, from the food industry demonstrates how this option may be used.

- A company has a "racking" production job where 20 trays are "racked" by using the Input Production transaction in DEACOM. Each finish on the "racking" job represents one of the trays being added to the rack.

- During the finishing process for the "racking" job, users select a Master Lot in the "Master Lot" field.

- Once all 20 trays are racked, the company creates a "freeze dry" production job to freeze dry these trays.

- At this point, the company needs the to issue the Master Lots from the "racking" job to the "freeze dry" job. The "Include Master Lots in Picklists" flag enables this ability.

- Finishing to Master Lots - User now have the option to finish inventory to Master Lots on the "Input Production" form via Production > Input Production. This feature has been available via the "Input Production" form in the WMS Application for a while. The ability was added to the Main Application to handle situations when scanners lose connectivity. Additional information on the process is available via the "Creating and Using Master Lots" page. Note this option is only available in the web versions of DEACOM.

- Staged Inventory Report - The "Staged Inventory" report has been added to Production > Job Management. Inventory may be final staged from this report via the "Final Staging Job" button located at the top of the report. See the Staging Material page for information on how to final stage inventory.

- Selecting Scale Model during Final Staging - The "Scale Model" field has been added to the Inventory Final Staging form to allow users to easily move between different Scales. This option is useful in situations when using different scales to weight larger or smaller items.

Additional information on Master Lots is available via the Creating and Using Master Lots page.

- Split Lots During Close/Relieve - Lots can be split on the Close/Relieve Job form via Production > Job Management.

- Make Master Lot During Close/Relieve - Users now have the ability to create a Master Lot for each lot that is being finished. See the Production > Job Management help page for details.

- Incremental Issuing Option – DEACOM now offers the ability to set issuing increments on the “Edit BOM Line” via Inventory > Formula Management. If the increment is non-zero, the system will replace the quantity in the "To Issue" column with this increment when issuing to jobs in the Main and WMS applications.

- Business Case – A customer required the ability to issue in batch size increments. They might have a job for 3000 LBS of a material but the batch tanks may only hold 100 LBS at a time. In this case the quantities that are being issued to this job need to respect 100 LB increments. Additional information is available via the “Issue Increment” field description via Inventory > Formula Management.

- Incremental Final Staging - Users have the option to set incremental final staging based on the "Job Staging Counts" value in System > Options. This option works with the "Incremental Issuing" feature above. Example: A Bill of Material contains Raw1/Raw2/Raw3 all set at 1 per for 1 finished good, each with an issuing increment of 100 and a job is created for 300 finished good. If job stage count = 3, the first time through the system will final stage 100 Raw1, 100 Raw2, then 100 Raw3 for iteration 1. The system will present 100 each of Raw1/Raw2/Raw3 for the 2nd and 3rd iteration of final staging. At the conclusion of the third iteration, all the inventory will be issued. If the "Job Staging Counts" is set to "1", the system will not allow you to final stage more than the increment + overissue% until a job finish complete.

- Under Issue Quantity % Limit - Companies can now set under issue % limits on the "Inventory 2" tab in System > Options and on the "General 2" tab in Inventory > Item Master Management. These limits are used when Issuing or Final Staging to Jobs.

- Gross and Tare Weight added to Input Production - The "Gross Weight" and "Tare Weight" fields have been added to the "Input Production" form via Production > Input Production. These fields are only enabled when the "Measurement Type" (dmunit.un_type) of the part being input is a weight type. The values added to these fields will be used to calculate the "Completing" field.

- Required to Create Job Work Flow - A new property field, "Required to Create Job," has been added to the Edit Work Flow Sequence form. If checked, no job may be created in the system, until the Work Flow Sequence on the selected BOM revision is marked as Complete.

- Gross and Tare Weight during Final Staging - The "Note Message Format" field has been added to the New Scale Model form. This field defines the information that will be defaulted to the "Notes" field on the "Inventory Final Staging" form when the "Read Weight" flag is checked. Designed for situations where customers want to capture the Gross and Tare weights during weigh up. Additional information is available via the link in the first sentence.

- Change User Lot Value - A new security setting "Inventory -- change user lot from modify lot" has been added to allow users to change the value of the User Lot when using the "Modify Lot" form on the "Lots", "Lot Summary", or "User Lot Summary" report. Additional information is available via the "Modify Lot" field description via Inventory > Inventory Management.

- Business Case - A customer has situations where they could realize halfway through a job that the color has changed on the product they are producing and will need to change the lot numbers on the previously produced inventory from that job. The inventory is still in Pending QC at that time.

Purchasing

- Vendor Specific Contact Information - The "Order Contact" search box on the "Misc 1" tab of Purchase Orders is now restricted to only display the CRM contacts that have same vendor on their contact record as the vendor selected on the Purchase Order.

- Recurring Orders against Blanket Orders - Recurring Orders may now be created to go against Blanket Purchase Orders. When copying the Recurring PO into a new PO, the system checks if any of the parts are part of a Blanket Purchase Order. If a match is found, the system will apply the price based on the appropriate blanket order. The blanket order quantity will be also be updated.

- Backordering for specific Items - Individual Items can now be set for backordering when receiving Purchase Orders. The feature is enabled via the "Allow Backorders When Receiving" flag on the Properties tab of the Item Master record and is used in conjunction with the "Accept Backorders" flag on the Vendor record. If the Vendor backorder flag is set to true, the system will now check the Item Master record to see if the "Allow Backordering When Receiving" flag is checked. If this flag is checked, the system will allow the backordering functionality to occur for this item. If the flag on the Item Master is not checked, backordering will not occur for this item, and the system will not put the remaining quantity from the Purchase Order into the "Backorder" field. The feature applies when receiving in the main application and via the DEACOM Warehouse Management System. Note that the "Allow Backorders When Receiving" flag is set to True by default when updating to version 15.02.036.

- Business Case - A customer orders 6500 gallons of an item but only receives 6495 gallons. In this case, they may never receive the additional 5 gallons and will want to uncheck the "Allow Backorder When Receiving" flag for that item. However, if they order 10 cases of an item and only receive 9, they will most likely want the remaining case.

Quality Control

- Shipping At-Risk Inventory - A new security setting, "Sales orders -- ship at-risk inventory" has been added to the system. When set to "No", users will not be able to ship at-risk inventory lots on orders set to an order type of "Sales Order" but will allow users to ship at-risk lots in Inter-Company Transfer orders. This security is useful in scenarios where customers will transfer materials between facilities before the QC is completed but they will not ship to their customers and do not want to be able to see the at-risk lots on sales order shipping forms in the system.

- QC Detail Report Additions - The fields in the Quality Control Group(dmqc) table are now available to the QC Detail Reports in Purchase Order Management and Job Management.

Sales

- Enhanced Copy Order Feature - The sales order copy order feature, available via the "Copy Order" button on the "Sales Order Entry" form, has been streamlined for easier use. Now, when users click the "Copy Order" button, the system will display a list of active sales orders for copying. Once an order is selected, users will be presented with the "Quantity" form which displays all item lines from the order. At this point, users may update the quantities as required and click the "Apply" button to complete the process. Additional information is available via the New Sales Order help page.

- BOM Calculations Available to Sales Orders - Bill of Material User Calculations are not available to Sales Order User Calculations. When Sales Order User Calculations are evaluated, the system will check to see if there is a facility specific default formula for the item being calculated in the facility specified on the sales order. If there is, the system will use the BOM calculations from that revision. If there is not, the system will check to see whether there is a non-facility specific revision marked as default. If so, the system will use the BOM calculations from that revision. If not, the system will not bring in any BOM user calculation value for the item.

- Bill-to/Ship-to User Fields - Bill-to and Ship-to User Defined Fields are now available to the grid layout on the "Bill-to and Ship-to Companies" report vie Sales > Bill-to / Ship-to Management.

- Splitting Lots for Negative Quantity Sales Orders - When shipping a negative quantity sales order and splitting a lot the system creates a separate system lot for each split lot.

- Subassemblies for Header or Line Jobs - A new field, "Include Subassemblies in Header & Line Jobs," has been added to the Item Master Properties tab. If checked, and a header or line job is created, the system will evaluate this Part's BOM for any items flagged as "Manufactured," and will check all levels of the BOM and automatically include Subassemblies deeper than the first level to the job.

- Historical Display Currency/Order Currency Conversion - In situations where the display currency selected is different then the currency on the order, Sales Order Management reports will now convert the amount on the displayed orders to the exchange rate of the display currency as of the sales order invoiced date.

- Pricing Orders, Quotes, and Cross Reference Parts - Users now have the ability to add parts requiring a customer cross reference part, without creating the cross reference, to Pricing Orders and Quotes. This is accomplished by granting users permission via the following two new security settings:

- Sales Orders -- override bill-to/ship-to cross reference required for quotes

- Sales Orders -- override bill-to/ship-to cross reference required for pricing orders

- Reserving Inventory to On-Hold Orders - A new security setting, "Sales Orders -- reserve to orders on-hold" has been added to allow reserving of inventory to orders with an order type of "Order On-Hold".

- Promotions Based On vs Applied On - Added in 15.02.034, users can now specify the quantity that qualifies a promotion to be added to a Sales Order as well as if the Promotion should be applied to the ordered quantity or the shipped quantity. More information on these fields can be found on the Promotions and Discounts page.

- Customer Statement Printed Date - The system will now write a record to the "Credit Notes" memo field on the Bill-to customer record every time a customer statement is printed for the selected Bill-to. The entry will contain the data and time the statement was printed as well as the first and last name of the user who printed the statement.

- Pricing Report Pre-Filter - A new field, "Pricing Report Pre-Filter," has been added to the Sales 1 tab in System > Options. The field offers users an option to save a Sales Order Management pre-filter that will be used when using the "Pricing" button on the Edit Sales Order Line form during order entry.

- Sales Order Minimum Margin Security - A new security setting, "Sales orders -- allow standard margin less than minimum margin," has been added. If set to yes, users will be allowed to set a unit price on sales order lines that will cause the standard margin of a part to go below the minimum margin.

Business Case - This option was added for scenarios in which companies have multiple contracts for a variety of customers and several different items and need the ability to isolate the inventory based on the fact that large amounts of inventory will be required to fulfill normal sales orders that have not yet been entered. Reserving the inventory to an on-hold order supports this process and allows the reserved inventory to show in MRP via the "+Reserved" column/row. No demand in MRP will be displayed in the (-M) Sales column/row due to the fact this is an on-hold order.

System Security

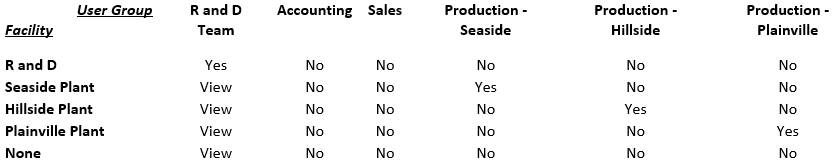

- Bill of Materials Security - Version 15.02 of DEACOM introduces a new, more powerful tool for maintaining Bill of Materials security. The new feature, available via System > System Maintenance > Revision Facility Security, allows companies to determine which Bill of Materials revision may be viewed and edited at the Facility level by User Group.

A Bill of Material (or BOM) revision, lists, in detail, all the items included when building a product. This information can be kept private for companies to maintain a competitive advantage in the marketplace. In addition, research and development teams may need to limit the visibility of revisions that are for lab use only and still a work in progress. If revisions for research and development are visible together with production revisions, this could lead to confusion and incorrect action on the part of inventory and production teams.

Example – A company maintains several manufacturing Facilities and one research and development Facility. Management stipulates that Formulators in the "R and D Team" User Group in the research and development Facility may be able to view and edit BOM revisions for their Facility, while granting access to view and copy revisions from all other Facilities. In DEACOM, the "Revision Facility Security" table would be set as follows.

- *The "None" Facility is used in DEACOM to secure access to those revisions that do not have a Facility specified. Additional information on revisions specific to Facilities is available via the Bill of Materials revision link above.

Update Note - When updating to version 15.02, all Bill of Material revisions, not just those assigned to a Facility, are defaulted to 'No'. This means users will initially be unable to view any BOM revision in DEACOM.

To correct this, navigate to System > System Maintenance > Revision Facility Security and toggle the "No" to "Yes" (for view and edit access) or "View" (for view only access) for the appropriate User Groups and Facilities. See the System > System Maintenance > Revisions Facility Security link above for complete setup information in DEACOM.

System Tools

- Linking Documents to Jobs in DEACOM - DEACOM now has the ability to link documents directly to jobs created in the system. Additional information and process steps are available via the Linking Documents to Records page. The ability to link documents to jobs was requested by several customers. One example of how this feature is used are situations in which batch tickets will be filled in manually by users and companies need the ability to attach the document to the job in DEACOM.

- Multiple Monitor Support - DEACOM version 15.02 introduces enhanced multiple monitor support. When users middle or right click on menu options or sidebar options in the DEACOM application, a new window will open displaying the selected menu option or transaction, provide the user has security to access the option or transaction. Note: Users will have to allow the deacom system's URL in their popup blocker or the popups may be blocked. This option is only available in web versions of DEACOM.

- Retain User's Printer Settings - A new field, "Retain Printer Setting After Logout," has been added to the user record via System > System Maintenance > Users. If this field is checked, and a new printer is selected via File > Settings, the system saves the user's printer selection in a cookie and reloads it on their next login as long as they are using the same browser. In this way, users will not have to continually reset their printer assignments each time they log in/out of DEACOM.

- Record Locking - Previously, an entire Job record was locked for editing. Starting in version 15.02.037, record locking works on a Job Line (dtljob) basis, rather than on the whole Job. This is especially helpful for companies that use one Job containing multiple Finished Good parts that are finished in different areas of the warehouse (bottling/canning/kegs), where users will have the Input Production form open for that same Job at the same time, inputting production on their respective parts (bottling/canning/kegs).

WMS

- AI 100 replaced with AI 250 - AI 250 is now used in DEACOM to represent the the container serial number in Supported Barcodes. AI 100 is no longer available for use in the system as result of conflicts with AI 10 which is used for barcoding User Lots.

- Select Lots Security - A new security setting, "WMS -- select lots when suggesting by location," has been added. When set to yes, this setting allows users to select the "Lots" button on the WMS Reserve Sales Order transaction even if the "Suggest By" system option is set to "Location." This is useful in situations where customers are using the snake picking feature in DEACOM and the lot in the suggested Location does not have enough of the material required. In this case, users will be able to select lots in another Location.

Work Flows

- Purchase Orders - Lock to Prevent Editing - The "Lock to prevent editing" flag can now be checked for Work Flow Sequences associated with Purchase Order Work Flow types. Additional information is available via the Edit Work Flow Sequence form help section.